Boost Product Longevity with a Durable Membrane Switch for Electronics

Boost Product Longevity with a Durable Membrane Switch for Electronics

Blog Article

Discover the Versatile Use Membrane Layer Switch in Modern Electronics

In the world of modern electronic devices, the application of membrane layer switches is extremely considerable, covering from smooth customer gadgets to important clinical gadgets. As industries continue to advance, the combination of membrane switches in equipment design is critical, appealing not just to satisfy however surpass the rigorous demands of both capability and visual charm.

Discovering the Duty of Membrane Switches in Consumer Electronic Devices

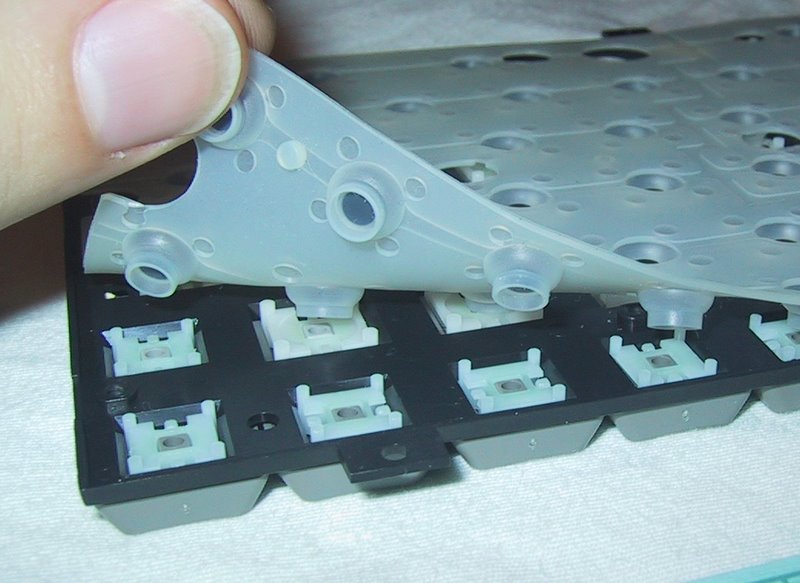

Why are membrane layer switches over so common in consumer electronics? The answer hinges on their distinct combination of integrity, flexibility, and price. Membrane layer buttons are cost-efficient to make, making them an attractive choice for high-volume manufacturing common in consumer electronic devices. Their construction, featuring a thin, versatile layer that can quickly be incorporated into different gadgets, enables streamlined, portable product designs.

Moreover, these buttons are understood for their durability and low upkeep. They are resistant to dust, dust, and wetness, which enhances the long life of the electronic gadgets they are utilized in. This reliability is crucial in daily customer products that go through constant usage. In addition, their adaptability in layout allows personalization in aesthetic appeals and functionality, dealing with the certain demands of different electronic devices. From microwave to push-button controls, membrane buttons supply a functional, user-friendly user interface that sustains the vibrant nature of customer electronics.

Membrane Switches in Medical Devices: Enhancing Interface

Membrane switches likewise play a substantial role in the world of medical tools, where they enhance individual interfaces with their distinctive advantages. These buttons are specifically valued for their dependability and ease of sanitation, important in healthcare settings where tidiness is paramount. The smooth, covered surface area of membrane changes enables for simple sanitation, reducing the risk of contamination and spread of pathogens. Their style flexibility accommodates the ergonomic and aesthetic demands of medical tools, making devices much more instinctive and obtainable for healthcare experts.

Membrane layer buttons also contribute to this page the durability of medical gadgets. Their resistance to liquids and contaminants makes certain that important equipment stays functional in different clinical setups, including surgical treatments where exposure to liquids is typical. This longevity, combined with tactile comments and inconspicuous design, makes membrane layer changes an essential component in boosting the effectiveness and safety and security of medical device user interfaces.

The Effect of Membrane Layer Switches on Industrial Devices Layout

In the realm of industrial equipment style, the consolidation of membrane buttons has actually marked a significant evolution. These switches have changed exactly how suppliers approach interface capabilities, providing a blend of durability and adaptability that is important in harsh environments. The slim profile of membrane changes enables more small device designs, while their resistance to water, chemical, and dirt contaminants makes them perfect for commercial settings. This versatility has facilitated the development of tools that is not only much more robust however additionally easier to keep and clean, consequently lowering downtime and operational prices.

Furthermore, the customizability of membrane layer switches allows developers to integrate specific tactile comments and visual overlays that improve the individual experience and rise performance. This combination supports operators in achieving precision control over complex equipment. The general influence is a fantastic read a significant improvement in the performance, integrity, and user-friendliness of commercial devices, aligning with the raising needs for technical advancement and functional efficiency in contemporary markets.

Final Thought

Membrane layer switches have changed contemporary electronic devices, using sleek, sturdy, and personalized user interfaces across various markets. Membrane Switch. In customer electronic devices, they improve the visual and capability of tools. Medical industries take advantage of browse around this web-site their trustworthy, user-friendly controls, critical for sensitive atmospheres. Similarly, industrial applications value their strength and efficiency. This innovation not just fulfills the demanding conditions of different areas yet additionally significantly boosts individual experience, making membrane changes a foundation of modern electronic style.

In the world of modern electronics, the application of membrane layer buttons is remarkably comprehensive, covering from streamlined customer gadgets to important clinical gadgets.Why are membrane layer changes so common in customer electronics? Membrane layer switches are economical to manufacture, making them an appealing choice for high-volume manufacturing regular in customer electronic devices. From microwave ovens to remote controls, membrane switches offer a practical, easy to use interface that supports the dynamic nature of customer electronics.

Report this page